Last modified:

The simulation in VCOM provides a real-time target value of expected power/energy for each of your PV systems. The simulation affects the following areas of VCOM:

-

Inverter simulation chart

-

Current system status portlet

-

Total outage alarms and Misproduction alarms: Separate configuration required. See Calculation methods for total outage and misproduction alarms.

Simulation parameters

Target range

The Target range is an acceptable deviation from the simulated, expected power/energy. It is a percentage that is applied to the simulation's target value on the Solar power chart. It is interpreted as +/-, that is plus and minus target range relative to the base value.

Example

-

The simulated target value for expected power/energy is 100%.

-

You enter an acceptable deviation for the Target range: 10%

-

This results in a target range of 90-110% for the expected power/energy.

Data outside of this range is considered a yield loss. For information on calculating yield losses, see Yield loss calculation.

Simulation methods

The following methods are used to estimate theoretical production. The method you choose depends on your system setup and preferences.

Target performance ratio (PR)

This is the default method and is a basic simulation based on the Target performance ratio.

Physical simulation

The physical simulation uses additional parameters to provide more accurate results:

-

Sensor irradiance: All irradiance sensors defined in a system are taken into account, depending on how they fit the production. This includes sensors connected to the data logger and sensors defined as a term.

-

Number of modules

-

Module power: maximum power points in the subsystem setup

-

Number of inverters

-

Inverter output power: rated output power

-

Power control correction value

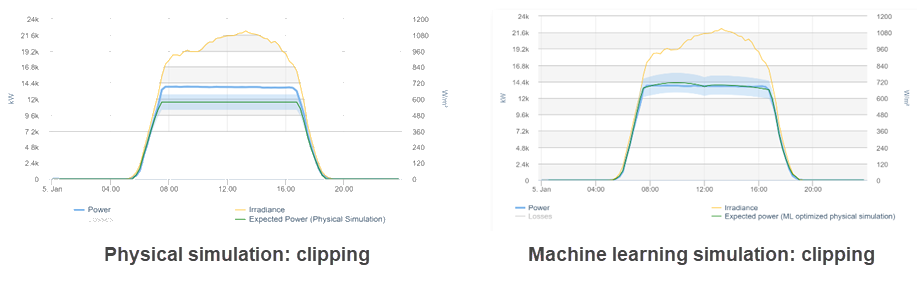

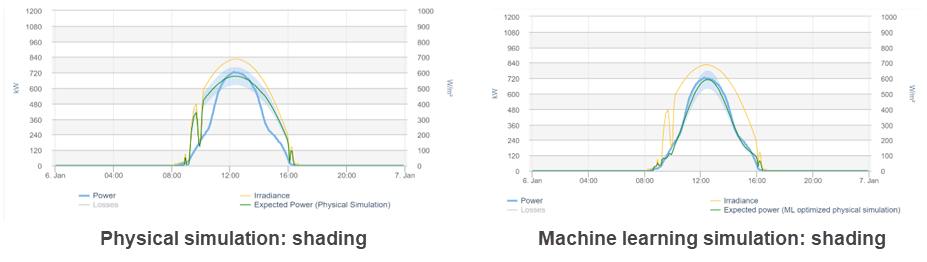

Machine learning simulation (artificial intelligence optimized simulation)

Machine learning algorithms analyze the historically measured data of the PV system and optimize the physical simulation. The machine learning simulation allows you to learn site-specific characteristics such as shading, clipping, and degradation.

Configure the simulation

Select the simulation method you want to use to calculate the expected power in the evaluation charts.

Steps-

At System level , go to

-

Select a percentage for the Target range.

-

Select the Simulation method.

-

Select

The selected method is now applied to calculations and the expected power/energy is displayed in the charts accordingly.

We recommend selecting a simulation method and target range once and only changing it if you want to compare which options display the best results for your system. When making any changes, be sure to select ![]()

![]()

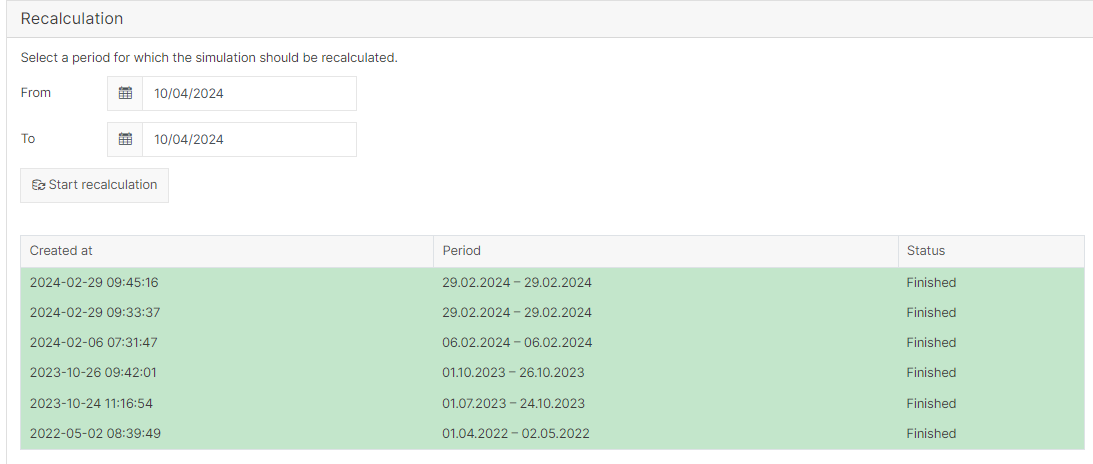

Recalculate simulation values

If you change a term, for example, an irradiance term, you may need to recalculate the simulation.

Example

If a sensor malfunctions, you will switch sensors. To ensure accuracy, this requires you to recalculate the simulation.

Note

Switching from one simulation method to another does not require recalculation.

-

At System level , go to

-

Under Recalculation, select the period you want to recalculate.

-

Select Start recalculation.

The recalculation will appear in the table below, and the recalculated values will be applied to the relevant charts.