Calculation methods for total outage and misproduction alarms

Last modified:

You can choose from the following methods to calculate expected power for both Misproduction alarms and Total outage alarms. The method you choose depends on your system setup and preferences:

Inverter comparison

Physical simulation

Machine learning simulation

Note

If you have selected a method that does not produce a value, and all your inverters fail simultaneously, a basic default calculation based on the sun's position will be performed. This calculation simply checks if power should be available, without considering the configured nominal power value.

Inverter comparison

For this method, the target value source is determined by comparing the inverters with each other. The respective input configuration is automatically considered. For this, all inverters are grouped based on their input ratios. Then the best-performing inverter (the one with the highest normalized power) is established as a reference for other inverters in that group. In the next step, the normalized power is considered a target value for the inverters being compared.

Prerequisites

All inverters are assigned to a subsystem.

Physical simulation

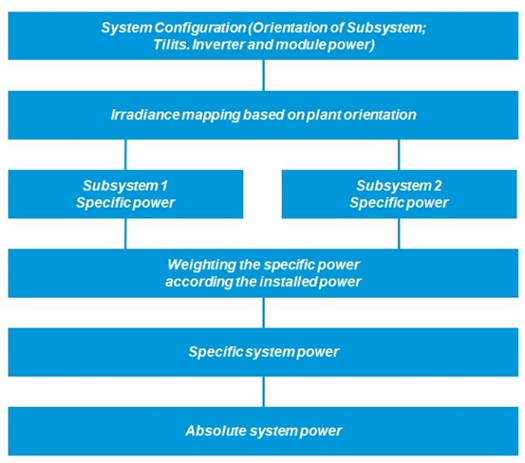

The simulation is based on irradiance values and system configuration. First, the specific power (from modules and inverters) is calculated for each orientation subsystem, defined by its tilt and azimuth.

Each subsystem is simulated using data from the irradiance sensor that most closely matches its orientation. This match is determined by correlating the subsystem’s power measurements with irradiance readings from available sensors.

Prerequisites

All inverters are assigned to a subsystem

At least one working irradiance sensor

Machine learning simulation

The machine learning simulation is similar to the physical simulation, but uses historical data for more accurate simulations. Machine learning algorithms analyze the historical measured data of the PV system and optimize the physical simulation. This reduces the deviation between the actual (measured) power and the target power to achieve the most accurate target value. To apply machine learning, the system must meet the following criteria:

Prerequisites

The number of inverters assigned to each subsystem has to match the number of inverters configured in that subsystem.

There are no "unknown" panels configured in any subsystem.

Manual correction of subsystem configuration is not taken into consideration.

70% or more of the daytime data points are valid.

At least two weeks’ worth of valid training data within the last 30 days is available.

If valid training data is missing, the machine learning-optimized simulation will not be available, and a message is displayed on the simulation configuration page.

Note

The physical and machine learning simulations are also relevant to the simulation used in charts. See Simulation.

Activate or change a calculation method

Go to

System configuration >

System configuration > .png?inst-v=7ecd2927-5901-45e0-b389-9cffc4aa6846) Monitoring > Alarms > Misproduction alarm (or Total outage alarm).

Monitoring > Alarms > Misproduction alarm (or Total outage alarm).Under Trigger criteria, select the desired simulation method.

Select Save.

The calculation method will now be applied to that alarm type.

.png)